Professional Separator Su325目石灰石粉生产线ide Cop石灰石r Flotation Machine

Floation Machine Manual FTM Machinery

Usage and Maintenance IJust protection as other on every mining machines, flotation separators need normally and even longer parts and regular maintenance to work be 独特的空气自循环系统,粉尘排量少,生产线可配备脉冲除尘器,除尘效率高,排放浓度低,基本实现车间无尘化作业。 编辑于 16:41 黎明重工 石灰石磨粉80425目,选用什么样的磨机合适? 知乎JXSC Machinery Factory is a professional R D and production manufacturer of flotation cells/machines Our froth flotation separation is sold all around the world and is popular Flotation Cells Machines JXSC Machine325目石灰石磨粉设备推荐! 石灰石主要成分碳酸钙。 石灰和石灰石是大量用于建筑材料、工业的原料。 石灰石可以直接加工成石料和烧制成生石灰。 生石灰CaO吸潮或加水就 325目石灰石磨粉设备推荐! 知乎专栏

(PDF) Flotation Equipment and Processes ResearchGate

2017年7月19日 floated Flotation Equipment To achieve this, a flotation machine must: Provide a quiescent pulp region immediately below the froth to minimize pulp This book highlights the principles and technologies of flotation machine mainly used in mineral processing in detail Froth flotation is one of the most important mineral Principles and Technologies of Flotation Machines石灰石磨粉生产线 免费设计方案 — 免费技术解答 物料处理工艺 核心设备:雷蒙磨 生产能力: 2120t/h 1 大块石灰石物料经颚式破碎机破碎机破碎后,再由反击式破碎机进行细 石灰石磨粉生产流程、石灰石生产线设备及生产工艺 Centrifugal Separator GEA separators are designed for liquidbased applications Using centrifugal force, they are used for separating suspensions consisting of two or more Centrifugal Separator Centrifuges and Separators

.jpg)

Flotation Machine Upsizing Method and Technology

2021年3月14日 This section will briefly introduce the upsizing technology of typical pneumatic mechanical agitation flotation machines, such as the TankCell flotation 2018年5月1日 The efficiency of the flotation process is a function of the probability of particlebubble collision, particlebubble attachment, and particlebubble detachment Flotation technique: Its mechanisms and design parametersFlotation machines constitute the basic equipment for useful minerals recovery from nonferrous ores and other raw materials by flotation They can operate also as individual flotation cells Flotation Cells (Froth Flotation Cells Machines JXSC MachineFlotation Machine 【Capacity】 01820m³/min per cell 【Feeding size】 200 mesh no less than 80% 【Type】 Agitating flotation machine, Selfpriming, aeration flotation, flotation column 【Model】XJK, SF, GF, Flotation Machine for Mineral Metallurgy JXSC

.jpg)

Professional Mineral Flotation Cell Separator Machine Gold

Professional Mineral Flotation Cell Separator Machine Gold Leaching Copper Refining Flotation Machine Manufacturers No reviews yet Henan Hongke Heavy Machinery Co, Ltd Custom manufacturer 16 yrs CNFlotation machines and columns are engineered to maximize the recovery of desired ore grade in various minerals processing applications Flotation machines maximize flotation performance for all roughing, cleaning and scavenging dutiesFlotation MetsoXFD12 Mechanical Cell Flotation is employed for agitation, separation, scrubbing, and cleaning of samples in labs of geological, metallurgical, building material, chemical, coal, beneficiation plant of mine, institutions of higher learning, and research institutions XFD12 laboratory multicell flotation machine is suitable for the flotation of nonferrous, black, XFD12 Mechanical Cell Flotation JXSC Machine2018年2月1日 This paper presents the results of an investigation into the influence of hydrodynamics on a preflotation process for the copper sulfide ore from the ForeSudetic Monocline deposits in Poland in a flotation machine The main aim of the preflotation stage for Polish copper ore is to remove the easytofloat organic matter — organic carbon — Influence of hydrodynamics on preflotation process in flotation machine

.jpg)

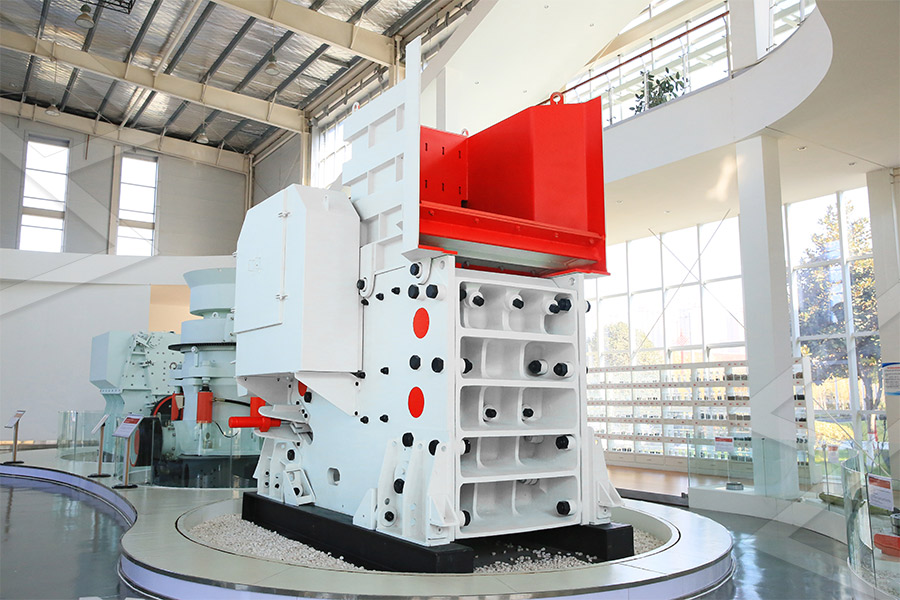

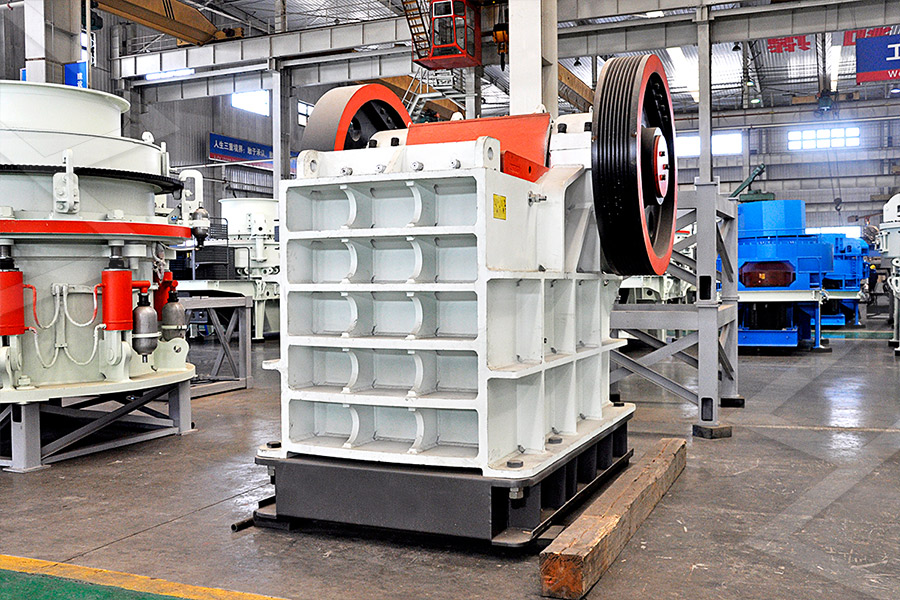

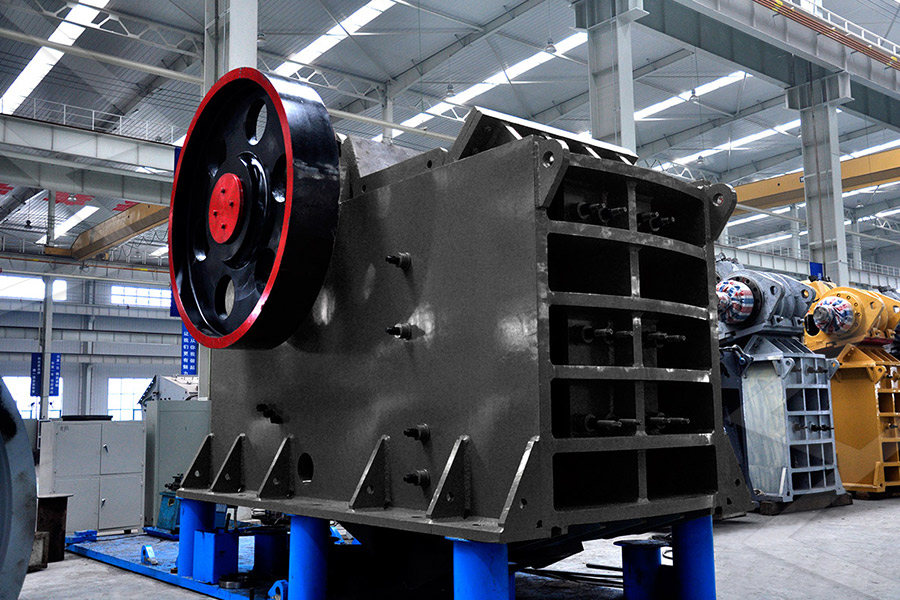

Types and Price of Flotation Machine Fote Machinery (FTM)

Flotation machine consumables: impeller, stator Flotation Machine Manufacturer Fote Machinery has various types of flotation machine for sale, in addition to froth flotation machine, we also have copper ore flotation machine The flotation machine produced by FTM company has advanced structure, reliable performance and favorable priceBased on the analysis and study of copper flotation process, this paper adopts partial least squares (PLS), kernel partial least squares (KPLS), least squares support vector machine (LSSVM) and long short term memory (LSTM) methods to predict the CCG for a copper flotation parative Study on Prediction Methods of Copper Concentrate SINTEF2022年5月6日 Flotation is a common mineral processing method used to upgrade copper sulfide ores; in this method, copper sulfide mineral particles are concentrated in froth, and associated gangue minerals are separated as tailings However, a significant amount of copper is lost into tailings during the processing; therefore, tailings can be considered The Challenges and Prospects of Recovering Fine Copper Sulfides Electrostatic Separator; Flotation Equipment Flotation Machine; Mixing tank; a mineral mixer tank with factory price, a flotation machine, and other gold mining equipment to obtain efficiency chemical tanks, steel We can satisfy your requirements with our professional expertise gained from 30 years of experience in the design Industrial Mixing Tank Mineral Flotation JXSC Machine

.jpg)

Floation Machine Manual FTM Machinery

FOTE FLOTATION MACHINE 04 The machine is used for feeding by vibrating It is suitable for mine selection, building materials, silicate and chemicals It can transfer and screen ore and rock with granularity less than 850mm ⅠIt is called mechanically agitated flotation machines ⅡThis machine is mainly composed of a slurry tank, a2023年11月30日 Novel perspectives in designing flotation circuits, machinery, and the minimization of energy consumption; Modification and improvement of flotation circuits; Numerical modelling of flotation Design, Modeling, Optimization and Control of Professional Copper Oxide Sulphide Ore Flotation Processing Plant, flotation machine, which is the ending machine in this flotation line) STEP 3: Flotating After this flotation machine, if you want to the dry Professional Copper Oxide Sulphide Ore Flotation Porphyry copper deposits (PCDs) are some of the most important sources of copper (Cu) and molybdenum (Mo) Typically, the separation and recovery of chalcopyrite (CuFeS2) and molybdenite (MoS2), the major Cu and Mo minerals, respectively, in PCDs are achieved by twostep flotation involving (1) bulk flotation to separate Cu–Mo concentrates and A Review of Recent Advances in Depression Techniques for Flotation

Mineralogical Prediction on the Flotation Behavior of Copper

2021年8月11日 “Table 8 demonstrates that the R max of each mineral slightly decreased with increasing the oxidation degree of the ore sample For instance, the R max of chalcopyrite in Sample B, the least oxidized ore sample, was the highest (ie, 0835) The R max of chalcopyrite wasFroth flotation is one of the most important and widespread methods of separation of minerals and waste materials and at the same time one of the most accurate methods of refining lowgrade metal minerals This paper presents a method for visual feature extraction of froth bubbles including the size, color, shape, and mobility based on machine vision A Machine Vision Based Method for Extracting Visual Features of 2019年9月29日 A new method, staged flotation for effectively increasing the recovery of ultrafine copper oxide ore with a new type of collector (ZH1, C35 carbon chain xanthate) is proposed for the first time The flotation process and mechanism were examined by flotation tests, entrainment rate analysis, laser particle size experiments and Minerals Free FullText A New Collector for Effectively MDPICopper Flotation Machine,Gold Flotation Separator Capacity 0204 Cubic Meter/Minute Power 15kw Impeller Dia 300mm Main Products Mining Feeder,Jaw Crusher,Ball Mill,Shaking Table Price Professional Manufacture Copper Concentrate Extraction Plant Mineral Machinery Lead Ore Flotation Separation Processing LineProfessional Factory: Copper Concentrate Extraction Machinery

XFD Ⅳ Single Flotation Cell JXSC Machine

【Structure】 The XFD Ⅳ flotation machine is composed of a frame part, main shaft drive part, lock part, scraper part, flotation cell, outside air inflation device, electric controller, etc, 【Working Principle】 The singlecell flotation machine (mineuse singlecell flotation machine) is driven by the triangular transmission of the motor to rotate the impeller, 2022年9月22日 Separation of chalcopyrite from molybdenite is currently mainly carried out by flotation, but this process is costly because of the extensive use of inhibitors This study briefly describes a 70T/100CGC Separation of CopperMolybdenum Flotation 2024年9月11日 Preparation process before separation Including copper ore crushing, screening, grinding, grading and other processes The purpose of this process is to separate useful minerals from gangue mineral Copper Ore Processing Plants, Flow And Equipment2022年11月1日 Chrysocolla is a copper oxide mineral with a complex structure, and it is characterized by multiphase inhomogeneity and multiple micropores The ideal molecular model of the chrysocolla unit cell is shown in Fig 1 [12]However, isomorphism exists in the molecular structure of chrysocolla because of impurityatom doping, resulting in Flotation of copper oxide minerals: A review ScienceDirect

.jpg)

Flotation Machine in Wide Application Fote Machinery

Flotation Machine Download Flotation Separator 85298 KB Applicable Materials: Nonferrous and ferrous metals, precious metals and nonmetallic minerals such as phosphorite, fluorite, leadzinc ore, copper ore, gold ore, iron ore, aluminum ore, lead ore, potash feldspar, quartz, etc摘要: Concentrate copper grade (CCG) is one of the important production indicators of copper flotation processes, and keeping the CCG at the set value is of great significance to the economic benefit of copper flotation industrial processesThis paper addresses the fluctuation problem of CCG through an operational optimization method Firstly, a density Operational optimization of copper flotation process based on Why choose Mecru? 01 Customized flotation process solutions Optimize resource allocation and reduce the use of flotation reagents 02 Compact, economical and efficient flotation plant layout and parameter configuration, reducing customer capital investment 03 Mature flotation process High flotation recovery rate and stable concentrate quality Flotation MachineMECRU2 Flotation: The finely ground ore slurry is mixed with a flotation agent The flotation agent type and amount will be selected according to the specific ore properties Send the slurry into the flotation machine The gold particles will be adsorbed on the air bubbles due to their unique properties, while other minerals will sink to the bottomGold Flotation Process, Equipment JXSC Machinery

How to Process Copper Ore: Beneficiation Methods and Equipment

2023年3月13日 Flotation machine for copper ore dressing Performance advantages of copper ore flotation machine The copper flotation machine increases the collision probability of coarse particles and foams, improves the mineralization effect of coarse particles, reduces the mismatch of materials and improves the recovery rate of concentrate2020年7月9日 It has been known that the power ultrasound is used as a pretreatment and rarely applied as a simultaneous method to improve grade and recovery during froth flotation processes This work aimed at investigating the impact of simultaneously used ultrasonic waves under variant operating configurations on the flotation of representative Minerals Free FullText An Improvement on Selective MDPI2019年10月14日 Effective fault detection techniques can help flotation plant reduce reagents consumption, increase mineral recovery, and reduce labor intensity Traditional, online fault detection methods during flotation processes have concentrated on extracting a specific froth feature for segmentation, like color, shape, size and texture, always leading Fault detection in flotation processes based on deep learning and 2018年7月26日 A nickelcopper sulfide system usually coexists with serpentine in deposits Low nickelcopper recovery and high content of serpentine in concentration adversely affects subsequent metallurgical The Critical Role of Pulp Density on Flotation

(PDF) Flotation Equipment and Processes ResearchGate

2017年7月19日 PDF This lecture is part of the annual Mineral Processing short course Find, read and cite all the research you need on ResearchGate2022年2月1日 Recycling spent batteries to recover their valuable materials is one of the hot topics within metallurgical investigations While recycling active materials (Li, Co, Ni, and Mn) from lithiumion batteries (LIB) is the main focus of these recycling studies, surprisingly, a few works have been conducted on the other valuable metals Copper and aluminum Recovery of Copper and Aluminum from Spent LithiumIon2024年7月5日 1 Introduction Today, the flotation method, in which many parameters are effective, remains one of the most significant enrichment methods According to Nagaraj [1] anything put into the flotation cell affects froth characteristics, as well as physical and operational parameters The identities that are described as collectors, frothers and Relation of bubble size, grade and recovery in the copper flotation 2021年9月30日 The mineral composition of copper–cobalt ores is more complex than that of copper sulfides, and it is also difficult to discard tailing efficiently in primary flotation for the finegrained disseminated of ore In this work, a mineral liberation analyzer (MLA) was employed to study the characteristics of minerals As a significant mineralogical Minerals Free FullText Flotation and Tailing Discarding of

Small Flotation XFDIII Single Cell Lab Flotation JXSC Machine

【Structure】 The XFD Ⅲ flotation machine is composed of a frame part, main shaft drive part, lock part, scraper part, flotation cell, outside air inflation device, electric controller, etc, 【Working Principle】 The singlecell flotation machine (mineuse singlecell flotation machine) is driven by the triangular transmission of the motor to rotate the impeller, 2019年9月27日 There are many types of flotation machines, JXSC mine machinery Company in China has more than 30 years of professional experience at the mining equipment rock crusher, gravity separator, magnetic separator, flotation machine, etc Contact Us Now 60757 LATEST PRODUCTS Suspended Vibration Cone Concentrator Types of Flotation Machines JXSC MachineOverview Copper Ore Flotation Processing Plant is mainly composed of jaw crusher, ball mill, spiral classifier, magnetic separator, flotation machine, ore concentrator and dryer machine combining with ore feeder, bucket elevator and belt conveyor which formed a complete ore beneficiation production line Advantage 1Low noise in construction site, Copper Ore Flotation Processing Plant China Copper Ore 2024年9月10日 Dasen Mining is a professional ore mining machinery, equipment manufacturer, supplier and mining solution provider for gold ore, copper ore, tungsten ore, tin ore, tantalum ore, chrome ore, manganese ore, iron ore, zircon ore, leadzinc ore etcDasen: all in one ore mining machinery, equipment, solution

.jpg)

A comprehensive review on aeration methods used in flotation machines

2024年1月5日 Novel flotation machines can generate midsized bubbles in the range of several hundred microns, such as the 100–400 μm bubbles generated in Microcel™ (Yoon, 1992), the 300–400 μm bubbles generated in a reactorseparator flotation machine designed by Russian researchers (Samygin et al, 2010), and the 100–600 μm bubbles Flotation machines constitute the basic equipment for useful minerals recovery from nonferrous ores and other raw materials by flotation They can operate also as individual flotation cells Flotation Cells (Froth Flotation Cells Machines JXSC MachineFlotation Machine 【Capacity】 01820m³/min per cell 【Feeding size】 200 mesh no less than 80% 【Type】 Agitating flotation machine, Selfpriming, aeration flotation, flotation column 【Model】XJK, SF, GF, Flotation Machine for Mineral Metallurgy JXSC Professional Mineral Flotation Cell Separator Machine Gold Leaching Copper Refining Flotation Machine Manufacturers No reviews yet Henan Hongke Heavy Machinery Co, Ltd Custom manufacturer 16 yrs CNProfessional Mineral Flotation Cell Separator Machine Gold

.jpg)

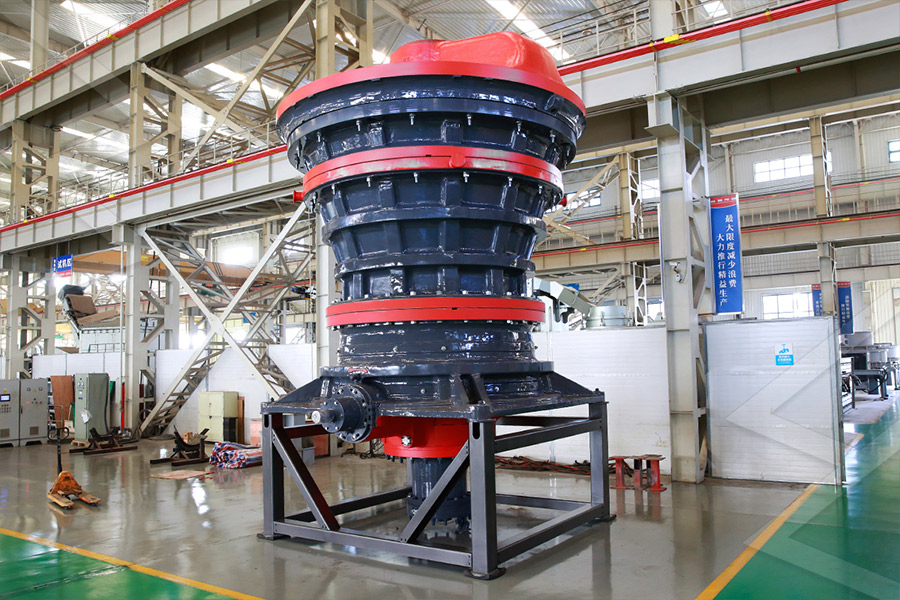

Flotation Metso

Flotation machines and columns are engineered to maximize the recovery of desired ore grade in various minerals processing applications Flotation machines maximize flotation performance for all roughing, cleaning and scavenging dutiesXFD12 Mechanical Cell Flotation is employed for agitation, separation, scrubbing, and cleaning of samples in labs of geological, metallurgical, building material, chemical, coal, beneficiation plant of mine, institutions of higher learning, and research institutions XFD12 laboratory multicell flotation machine is suitable for the flotation of nonferrous, black, XFD12 Mechanical Cell Flotation JXSC Machine2018年2月1日 This paper presents the results of an investigation into the influence of hydrodynamics on a preflotation process for the copper sulfide ore from the ForeSudetic Monocline deposits in Poland in a flotation machine The main aim of the preflotation stage for Polish copper ore is to remove the easytofloat organic matter — organic carbon — Influence of hydrodynamics on preflotation process in flotation machine The Introduction of Flotation Machine Flotation machine, also called flotation cell, is the equipment to complete the flotation process It is widely used for the rough, fine and reverse flotation operations of copper ore, lead ore, zinc ore, nickel, molybdenum and other nonferrous metal, ferrous metal and nonmetal mineralsTypes and Price of Flotation Machine Fote Machinery (FTM)

Comparative Study on Prediction Methods of Copper Concentrate SINTEF

Based on the analysis and study of copper flotation process, this paper adopts partial least squares (PLS), kernel partial least squares (KPLS), least squares support vector machine (LSSVM) and long short term memory (LSTM) methods to predict the CCG for a copper flotation process2022年5月6日 Flotation is a common mineral processing method used to upgrade copper sulfide ores; in this method, copper sulfide mineral particles are concentrated in froth, and associated gangue minerals are separated as tailings However, a significant amount of copper is lost into tailings during the processing; therefore, tailings can be considered The Challenges and Prospects of Recovering Fine Copper Sulfides Mineral mixing tank, also known as mixing tank, mineral mixing tank with an agitator, is widely used for mixing pulp before the flotation process/leaching process/CIP process, to make the pulp and medicament mixed intensively, creates the condition for the Mine selection working As a leading global manufacturer of the mining machine, JXSC is Industrial Mixing Tank Mineral Flotation JXSC Machine