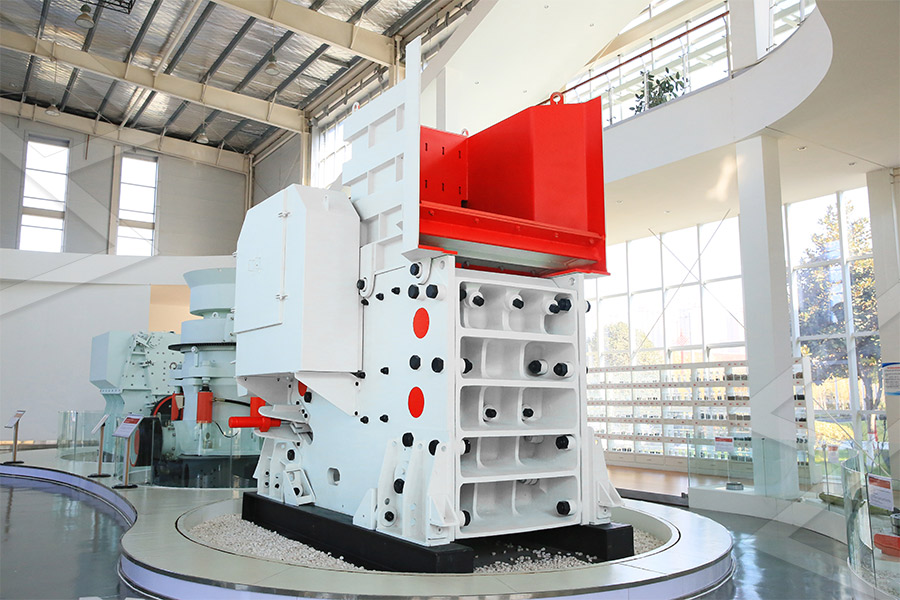

Grinding Jaw Crushers

Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

RETSCH jaw crushers are powerful forcedfeed crushers, available in 7 sizes They are used for sample crushing on a laboratory scale, but, depending on the model, can also BB 50 是 RETSCH 颚式破碎机系列的最小型号,专为实验室样品制备而设计。 创建PDF2017年6月2日 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such How it Works: Crushers, Grinding Mills and 2024年4月19日 There are two main types of jaw crushers: simpletoggle and doubletoggle A singletoggle jaw crusher is simpler in design and is widely used because of its low cost and ease of maintenance On the Types of Crushers Explained: Everything You

.jpg)

The Essential Role of Jaw Crushers in Ore

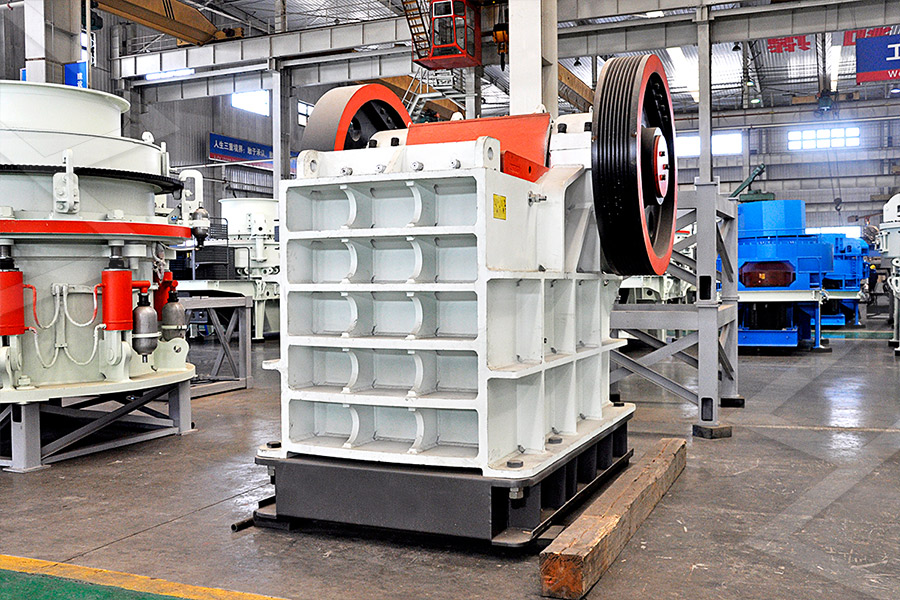

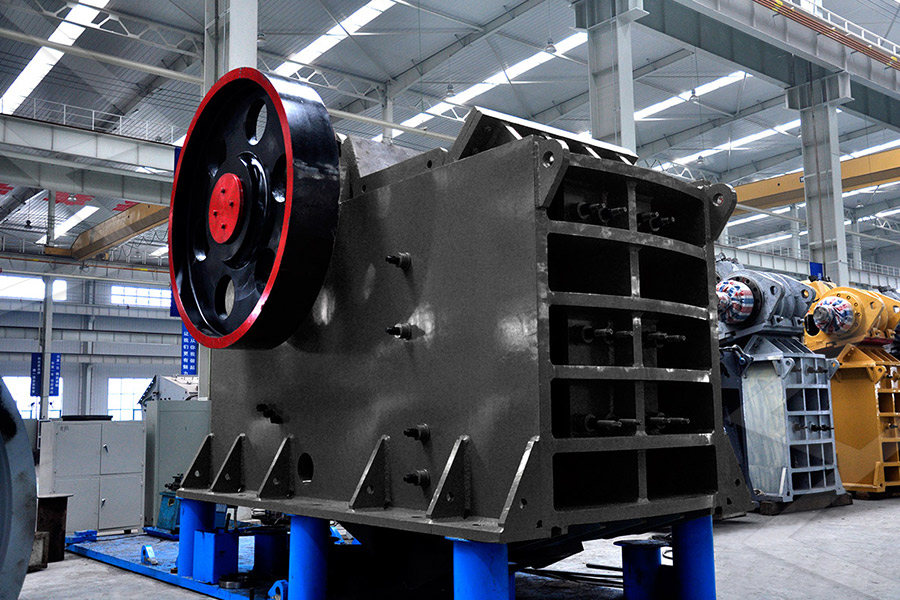

2024年2月6日 Jaw crushers are absolutely vital in the mining world, helping us break down raw materials into something we can actually use With all the different kinds of jaw crushers out there, you’re sure to find 2014年9月1日 It is well known and taken for granted that the efficiency of energy use by comminution (ie breaking, crushing, grinding) equipment is very low, typically less than Assessing the energy efficiency of a jaw crusher ScienceDirect2024年7月17日 Jaw Crusher Jaw crushers use the compressive and bending action of a fixed jaw plate and a movable jaw plate to crush materials of various hardnesses When Types of Crushers: Choosing the Right One for Each Stage2024年9月12日 A jaw crusher is a machine that breaks down large rocks into smaller pieces of rock, gravel, or dust It does this by placing two jaw plates perpendicular to each other and squeezing the rock between them Jaw Crusher: What Is It How Does It Work?

jaw crusher 百度百科

Jaw crusher can reach the crushing ratio of 46 and the shape of final product is even It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as 160 kW (250 hp) Sandvik crushing and screening equipment Unrivaled jaw crushers, cone crushers, gyratory crushers, impact crushers and more for mining and construction Stationary crushers Stationary crushing and screening SRP2019年5月30日 Jaw crushers have a multitude of advantages, including: Ability to handle many different types of materials—from hard granite to reclaimed asphalt pavement (RAP) and more—without displaying5 Common Questions about Jaw Crushers 2024年2月6日 Jaw crushers are absolutely vital in the mining world, helping us break down raw materials into something we can actually use With all the different kinds of jaw crushers out there, you’re sure to find The Essential Role of Jaw Crushers in Ore

Jaw Crushers high quality and reliability from

The crushing ratio of a jaw crusher results from the maximum achievable final fineness in relation to the maximum feed size For Retsch jaw crushers, this lies between 26 and 220 A high value reflects the capacity of a jaw 2023年2月21日 Jaw crushers are a popular choice for crushing and reducing the size of various materials, but like any type of crusher, they have both advantages and disadvantages Advantages of Using a Jaw The Ultimate Guide to Jaw Crushing Machines: Jaw Crushers for precrushing of very hard, hard, mediumhard, brittle, tough, The sample is crushed under high pressure between one fixed and one movable crushing jaw The grinding parts are available in various steel types, hardmetal tungsten carbide and zirconium oxide to prevent undesired abrasionJaw Crushers – fritsch2024年7月15日 But the production of gyratory crusher is much higher than jaw crushers' Therefore, if you require a large production and no focus on particle shape, you can choose gyratory crusher, Vice versa If your production demands below 1000 t/h, jaw crusher is the best choice and performs better when being applied undergroundWhat Are the Differences Between The 7 Types of Crushers?

.jpg)

Crushers, Pulverizers, Grinders Lavallab

2024年9月12日 Initial Top Size: Final fineness: Description: Max Capacity: Grinding Elements: Model: Jaw Crushers, Cone Crushers, Roll Crushers: 165 mm: 65 mm: Jaw crusher2024年9月12日 Applications Of Jaw Crushers Jaw crushers are used in various applications, from construction to mining and materials processing Some common uses for jaw crushers include: 1 Breaking up large rocks into smaller pieces for construction projects 2 Separating minerals from ore to extract valuable metals like gold or silver 3Jaw Crusher: What Is It How Does It Work? VYKIN Crushers1 天前 Cone crushers, vertical shaft impactors (VSIs), horizontal impact crushers, or even highpressure grinding roll crushers may be used in the final reduction position Types of Rock Determine the Crushers You Need Sandstone, limestone, gravel, and granite are arguably the most common aggregates used in the construction industry today, but these Types of Rock Crushers Quarry Crushing Equipment KemperWith continuous developments and new calculation methods from bionics, we’ve been able to make our latest generation of jaw crushers particularly compact and robust Thanks to its modular and maintenancefriendly design, our Jaw Crusher EB Pro series is ideally suited for use in both underground and opencast applications, when processing even Jaw crusher EB FLSmidth

.jpg)

Jaw Crusher: Range, Working Principle, Application DSMAC

2022年2月22日 Jaw crushers are used as primary crushers, or the first step in the process of reducing rock They crush primarily by using compression The rock is dropped between two rigid pieces of metal, one of which then moves inwards towards the rock, and the rock is crushed because it has a lower breaking point than the opposing metal piece2019年5月30日 Jaw crushers have a multitude of advantages, including: Ability to handle many different types of materials—from hard granite to reclaimed asphalt pavement (RAP) and more—without displaying as 5 Common Questions about Jaw Crushers Unlike ordinary toggle jaw crushers and a hinged opening allows for fast and easy cleaning of the grinding chamber A safety switch and brake motor ensure immediate shutdown if the jaw crusher is incorrectly opened or switched on Additionally, the fixed crushing arm can be easily and safely removed for cleaning and jaw replacement Fine Jaw Crushers FLSmidth2024年2月20日 For example, in a largescale copper mine, a jaw crusher plays a crucial role in breaking down huge chunks of ore before they're further processed in grinding mills Built to Last: Jaw crushers are made What's the Difference: Impact Crusher vs Jaw

Mining Crushers, Breakers and Grinding Mills Suppliers

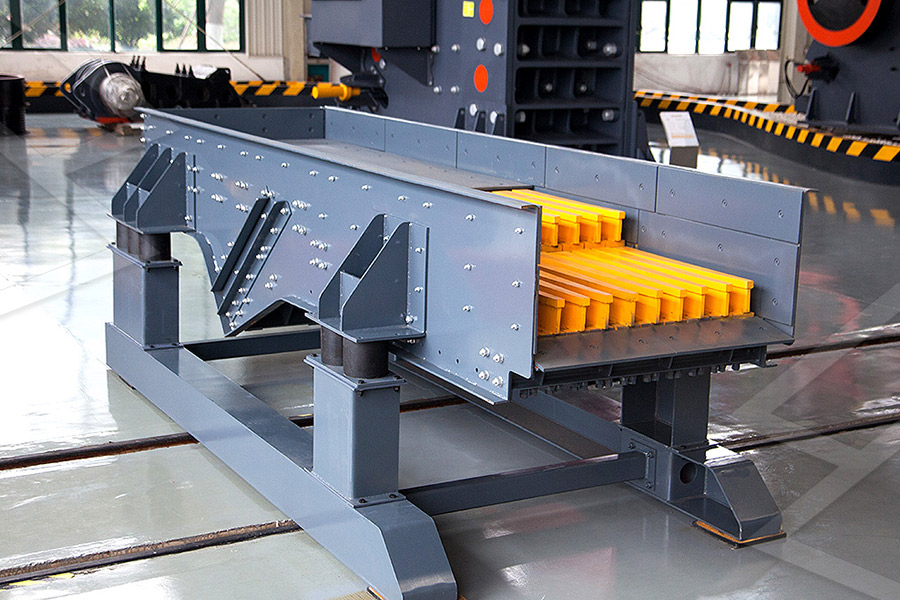

Finding suppliers of mining crushers, breakers and grinding mills Crushers, breakers and grinding mills come in several different types Mining Technology has listed some of the leading suppliers of processing equipment in the mining drills and breakers market, based on its intel, insights and decades of experience in the sector The list includes suppliers Crushers include offers jaw crushers, hammermills, cone crushers, and roll crusher options, each with multiple models, and designed for performance on harder materials such as ores, minerals, coal, and rock Pulverizers efficiently reduce aggregate, mineral or coal sample particle sizes using grinding plates, hammermills, or centrifugal impactCrushers, Pulverizers Mills Gilson Co GlobalGilsonChina LIMING Heavy Industry Science and Technology Co LTD which mainly manufacture large and mediumsized crushing and grinding equipments was founded in 1987 It is a modern jointstock corporation with research, manufacturing and sales together GF vibrating feeders are suitable for feeding equipment such as jaw crushers, primary impact Stone Crushers, Mill and GrindingOur crushing and grinding products work together with our heavyduty vibrating screens and washing equipment to deliver reliable solutions across the toughest mining, Our range of heavyduty Trio® jaw crushers use compression force to break large rocks into smaller rocks by squeezing them between a fixed and mobile jaw dieTrio® Crushing Equipment Weir

Jaw Crushers Glen Mills, Inc

2024年9月6日 Grinding Milling, Jaw Crushers BB 600 Jaw Crusher 0 out of 5 (0) The Jaw Crusher BB 600 is used for rapid, effective, crushing and precrushing of mediumhard, hard, brittle and tough materials Due to the low installation height (1 m), the BB 600 is ideally suited for continuous operation in automatic installations and sampling stations 2024年2月5日 In jaw crushers, the crushing force is generated by the movement of the movable jaw plate towards the fixed jaw plate This force is a result of the mechanical pressure created by the eccentric shaft and transmitted through the toggle plate The interesting thing is how these forces are applied to the material The crushing force is not How Does a Jaw Crusher Work? A Simple Guide JXSC212 Grinder After crushing the material, more detailed operations need to be carried out Jaw crushers are mainly used as primary crushers to produce material that can be transported by belt conveyors to the next crushing stages The crushing process takes place between a fixed jaw and a moving jaw The moving jaw dies are mounted on a Crusher an overview ScienceDirect Topics2023年12月30日 Jaw crushers are utilized to crush raw materials in the ceramics and glass industries, facilitating the production of finely ground materials for manufacturing processes Buildmate: Pioneering Introduction to Jaw Crushers: Understanding the

Jaw Crusher Explained saVRee

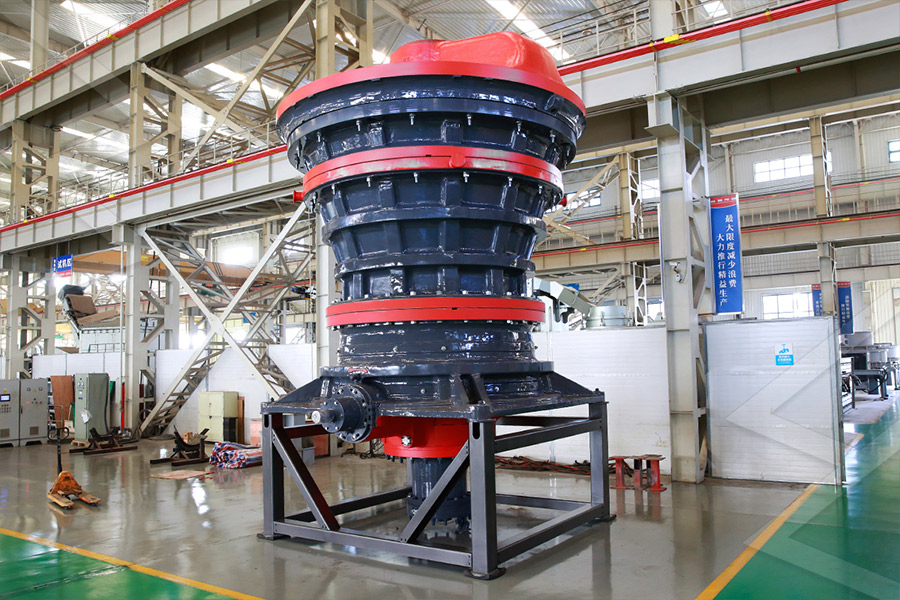

Jaw Crusher; Cone Crusher; Crusher Types (jaw, cone, gyratory) Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers It is often the case that there will be only one crusher installed, Buy used Jawcrushers from AM King Industries We can help guide you to the best solution for your equipment needs Used Mining Processing Equipment Grinding Mills, Crushers Process PlantsUsed Jawcrushers For Sale AM KingVisitors are invited to visit Booth No L03, where Liming Heavy Industry will showcase its latest mobile crushers and stationary crushing plants As a leader in the mining industry, the company is known for its innovative solutions designed to enhance efficiency and sustainability in mining Industryrock crushing screening grinding plant manufacturerCompressive crushers that press the material until it breaks, and impact crushers using the principle of quick impacts to crush the material Jaw crushers, gyratory crushers, and cone operate according to the compression principle Impact crushers, in turn, utilize the impact principle Jaw crushers Jaw crushers are mainly used as primary Crushers All crusher types for your reduction needs Metso

.jpg)

Crushing Metso

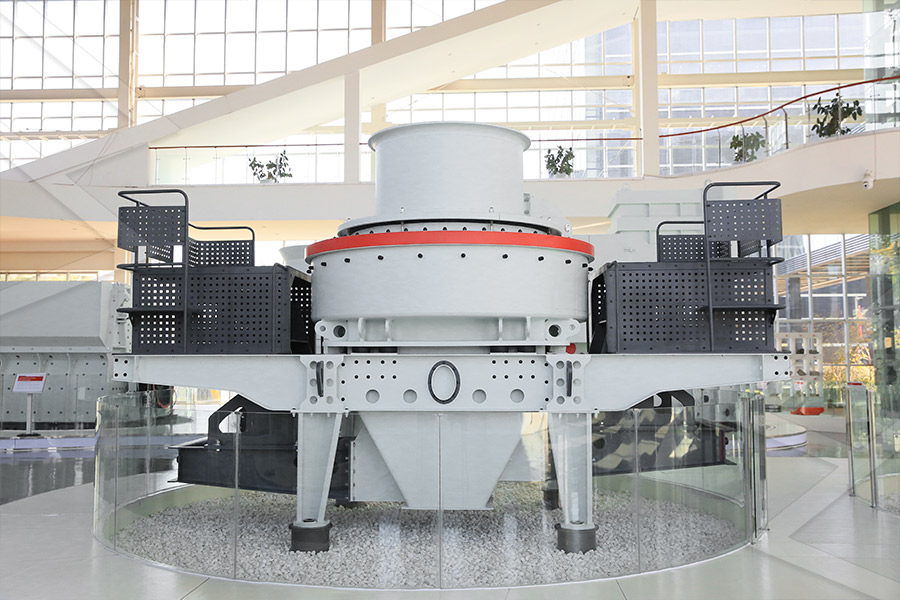

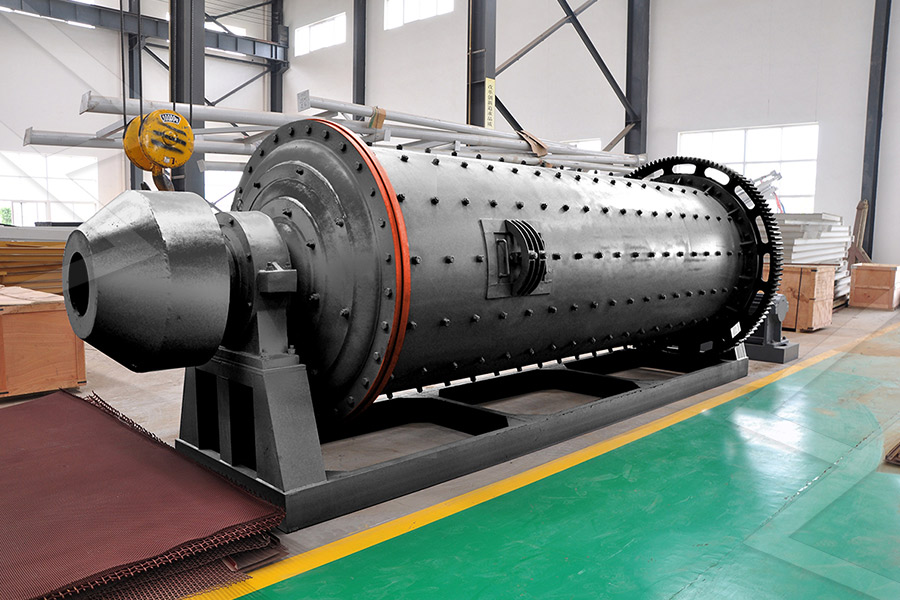

From large primary jaws and gyratories to cone and impact crushers for tertiary and quaternary finishing, Metso equipment is manufactured to meet your material reduction requirements The crushers are built to perform with the lowest cost per ton, featuring a unique combination of crusher cavity design, crushing forces, reliability and safety2023年10月8日 1 Jaw crusher The jaw crushers are popular primary crushers for coal They are often used in mines and quarries where large amounts of coal are mined The working principle of the jaw crusher is to use compression force to compress coal between a fixed jaw and a movable jaw for coarse crushing6 Types of Coal Crusher: Which Is Best for Crushing My Coal?2024年9月9日 The ball grinding mill machine usually coordinates with other rock crusher machines, like jaw crushers, and cone crushers, to reduce the ore particle into fine and superfine sizes Ball mill grinding tasks can be done under dry or wet conditions Get to know more details about rock crushers, and ore grinders, contact us!Industry Grinder for Mineral Processing JXSC MachineThere are cone crushers, jaw crushers, impact crushers, hammer crushers, etc Learn more Sand making equipment Grinding equipment Industrial milling equipment mainly includes SRM vertical mills, MTW European version mills, highpressure suspension 蜜桃影像台湾SWAG黄瓜视频

.jpg)

What Are The Different Types Of Crushers?

2024年9月12日 1 Jaw Crushers Jaw crushers are one of the most commonly used types of crushers due to their versatility They are suitable for crushing various materials from soft to hard and are therefore also referred to as compression crushers In terms of operation, jaw crushers work by compressing materials between two opposing plates, one movable 2024年2月6日 Jaw crushers are absolutely vital in the mining world, helping us break down raw materials into something we can actually use With all the different kinds of jaw crushers out there, you’re sure to find The Essential Role of Jaw Crushers in Ore The crushing ratio of a jaw crusher results from the maximum achievable final fineness in relation to the maximum feed size For Retsch jaw crushers, this lies between 26 and 220 A high value reflects the capacity of a jaw Jaw Crushers high quality and reliability from 2023年2月21日 Jaw crushers are a popular choice for crushing and reducing the size of various materials, but like any type of crusher, they have both advantages and disadvantages Advantages of Using a Jaw The Ultimate Guide to Jaw Crushing Machines:

.jpg)

Jaw Crushers – fritsch

Jaw Crushers for precrushing of very hard, hard, mediumhard, brittle, tough, The sample is crushed under high pressure between one fixed and one movable crushing jaw The grinding parts are available in various steel types, hardmetal tungsten carbide and zirconium oxide to prevent undesired abrasion2024年7月15日 But the production of gyratory crusher is much higher than jaw crushers' Therefore, if you require a large production and no focus on particle shape, you can choose gyratory crusher, Vice versa If your production demands below 1000 t/h, jaw crusher is the best choice and performs better when being applied undergroundWhat Are the Differences Between The 7 Types of Crushers?2024年9月12日 Initial Top Size: Final fineness: Description: Max Capacity: Grinding Elements: Model: Jaw Crushers, Cone Crushers, Roll Crushers: 165 mm: 65 mm: Jaw crusherCrushers, Pulverizers, Grinders Lavallab2024年9月12日 Applications Of Jaw Crushers Jaw crushers are used in various applications, from construction to mining and materials processing Some common uses for jaw crushers include: 1 Breaking up large rocks into smaller pieces for construction projects 2 Separating minerals from ore to extract valuable metals like gold or silver 3Jaw Crusher: What Is It How Does It Work? VYKIN Crushers

Types of Rock Crushers Quarry Crushing Equipment Kemper

1 天前 Cone crushers, vertical shaft impactors (VSIs), horizontal impact crushers, or even highpressure grinding roll crushers may be used in the final reduction position Types of Rock Determine the Crushers You Need Sandstone, limestone, gravel, and granite are arguably the most common aggregates used in the construction industry today, but these With continuous developments and new calculation methods from bionics, we’ve been able to make our latest generation of jaw crushers particularly compact and robust Thanks to its modular and maintenancefriendly design, our Jaw Crusher EB Pro series is ideally suited for use in both underground and opencast applications, when processing even Jaw crusher EB FLSmidth2022年2月22日 Jaw crushers are used as primary crushers, or the first step in the process of reducing rock They crush primarily by using compression The rock is dropped between two rigid pieces of metal, one of which then moves inwards towards the rock, and the rock is crushed because it has a lower breaking point than the opposing metal pieceJaw Crusher: Range, Working Principle, Application DSMAC