Investment Cost $ Or € Msw Ball Mill

.jpg)

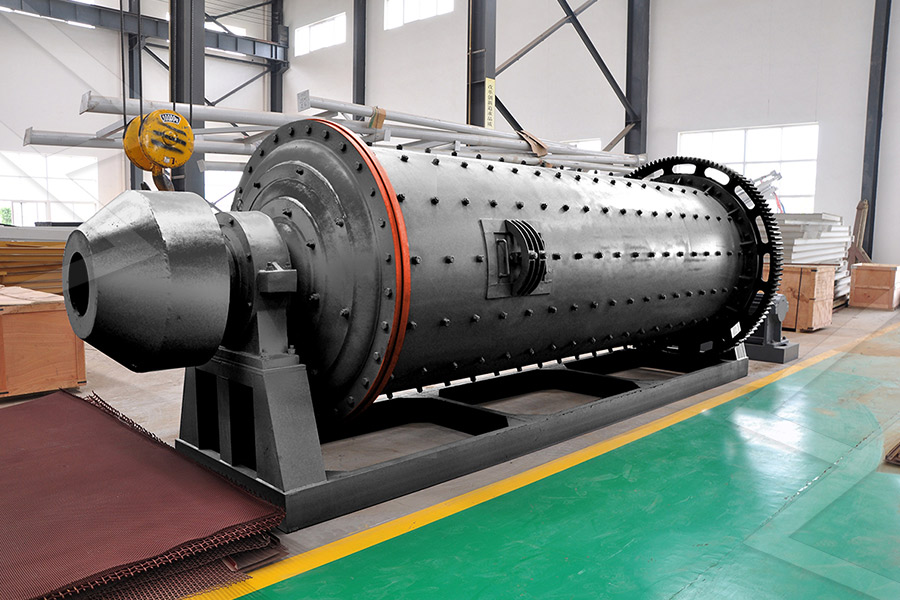

BALL MILLS Ball mill optimisation Holzinger Consulting

2021年3月12日 Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide significant cost and CO2024年6月24日 The size and type of the ball mill directly impact the cost of operationslarger mills generally require more capital investment but can process more material per unit of time, resulting in lower operational costs The cost difference between small and large mills can be substantialEstimating the cost of ball mill operations NEWS SMMVIK 2021年5月8日 Lameck’s work indicated that: Higher torque (power draw) can be achieved with increased packing efficiency – particularly for worn ball media At lower mill speeds, the cylpebs and new media draw higher power draw than the worn media and ballsRethinking Grinding Efficiency in Ball Mills RELO 2013年2月26日 Usually, a compromise is found between the PSD curve and energy consumption, as the above actions reduce the grinding efficiency and therefore increase the mill’s power consumption Investment cost A VRM is a compact unit, making the footprint of the installation smaller and reducing the civil engineering costs when compared to a ball Comparing ball mills and VRMS for cement grinding

.jpg)

Modeling of the planetary ballmilling process: The case

2016年8月1日 A numerical dynamicmechanical model of a planetary ballmill is developed to study the dependence of process efficiency on milling parameters like ball size and number, jar geometry and velocity of the revolving parts Simulations provide evidence of the correlation between milling parameters and the resulting microstructure of the ground 4 天之前 Ball mills are widely used in the mining and mineral processing industries for fine grinding and mixing materials The selection of the appropriate ball mill is critical to ensuring efficient and effective operationTechnical specifications and selection guide for ball millsBall milling is a simple, fast, costeffective green technology with enormous potential One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical modification of Ball milling: a green technology for the It’s also the biggest investment equipment of mill plant, and the wastage of the ball mill has a direct relationship with mill plant operating costs Therefore, it is very important to maintain and overhaul the ball mill Cement Ball Mill Maintenance INFINITY FOR

Ball Mills in the Mineral Processing Industry

2024年5月27日 The General Function of Ball Mills A ball mill is a grinder used for grinding and blending materials for mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering This 04L planetary ball mill machine features a compact design that fits in a glove box MSE PRO 4L (4 x 1L) Vertical High Energy Planetary Ball Mill with Touchscreen Controller Tired of old fashioned LCD control panels? Planetary Ball Mills MSE Supplies LLC2022年11月30日 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size Ball Mill: Operating principles, components, Uses, 2024年9月4日 New and Used Ball Mills insights There are 1 Ball Mills for sale in Australia from which to choose Overall 97% of Ball Mills buyers enquire on only used listings, 3% on new and 979% on both new and used Ball Mills items Buyers usually enquire on 169 different Ball Mills classifieds before organising finance Ball Mills are listed between Ball Mills New or Used Ball Mills for sale Australia

.jpg)

Planetary Ball Mill PM 300 RETSCH laboratory equipment

The Planetary Ball Mill PM 300 is a powerful and ergonomic benchtop model with two grinding stations for grinding jar volumes up to 500 ml This setup allows for processing up to 2 x 220 ml sample material per batch Thanks to the high maximum speed of 800 rpm, extremely high centrifugal forces result in very high pulverization energy and 2019年8月14日 Moreover, the price of ball mills is relatively expensive among many beneficiation equipment Therefore,after successfully purchasing a ball mill, it is necessary to carry out daily maintenance and maintenance of the ball mill The replacement of the ball mill liner is an indispensable maintenance workThe Ultimate Guide to Ball Mills Miningpediainvestment cost 24 or 2 82 msw ball mill Ginning mill project ginning mills for sale ginning mill for sale apartmanlipnorent 47 profile on cotton ginning plant embassy of pdf cotton ginning is the process of separating cotton seed from the lint so that the lint will be baled and goes to textile industries forInvestment cost 24 or 2 82 msw ball millSmall ginning mills Investment Cost Or Msw Ball Mill MC Machinery2022年7月12日 Vertimill® has 50% less footprint than a ball mill Lower operating cost Vertimill® is an energy efficient grinding machine They tend to grind more efficiently than, for example, ball mills with feeds as coarse as 6 mm to products finer than 10 microns This provides up to a 40% higher energy efficiencyStirred mills Metso

.jpg)

investment cost $ OR MSW ball mill forndelpontes

The initial investment cost (turnkey cost) includes the exworks price of the equipment needed (wind turbines, battery bank, electronic equipment, etc) and the corresponding installation cost The application of new technological achievements and the economies of scale decrease most system component prices in the international marketCondition: ready for operation (used), Ball Mill, Grinder, Crusher , Used machine Overall dimensions: 5950 x 2200 x 2005 Weight: 16 tons Power: 75 kW Roller diameter: 1264 mm Roller length: 3710 mm With 6366 HRC armor (in good condition, 4 cm thick) K7Ipfdyhsp Equipped with a frequency converter Built on a steel frame Grinding capacity: Fineness Used Ball Mill for sale MachineseekerThe ball mill diagram shows the main parts of a ball mill, including the feeding device, the cylinder, the discharge device, the hollow trunnion, the transmission device, the gear cover, the girth gear, the pinion, and the The Ultimate Guide to Understanding Ball Mill 2023年6月12日 A ball mill is a type of grinder that uses metal balls or other grinding mediums to reduce the size of various materials The material to be ground is placed in a cylindrical container that spins on its axis The What is a Ball Mill? Economy Ball Mill

Choosing the Right Laboratory Ball Mills Union Process

How to Select the Right Mill for Your Needs Having a laboratory mill on your premises offers a number of advantages, but you need the right equipment to get the most benefit from your investmentWhen evaluating lab mills, you should keep in mind the following considerations: SpeedEfficiencyBatch sizeMaterialStarting particle sizeTarget particle sizeProcess mode The noise produced in these ball mills, which make them ideal for laboratory use Using them, one can grind powder samples in vacuum state as well, if vacuum mill jars are present in the ball mill One gets to see excellent workmanship on all the equipment available here Quality of the equipment available on our website is guaranteed to be Laboratory Ball Mill, Planetary Ball Mill– MSE Supplies LLCCrushed ore is fed to the ball mill through the inlet; a scoop (small screw conveyor) ensures the feed is constant For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 3045%) Pulp (crushed ore and water) fills another 15% of the drum’s volume so that the total volume of the drum is 50% chargedBall Mill (Ball Mills Explained) saVRee saVReeThe vertical ball mill has stable performance, supports dry and wet grinding, and has unique performance for coarse and thickened materials Vertical ball mill can be widely used for dispersion and grinding of solid or powder materials in paint, medicine, building materials, chemical industry and other industriesVertical Ball Mill

.jpg)

Ball Mills Economy Ball Mill/JSB Industrial Solutions Inc

Economy Ball Mill, a division of JSB Industrial Solutions, Inc manufactures Ball Mills that are diverse in applications and uses Since we are an OEM and our product line has been around for over 50 years, we can provide the experience and knowledge to enhance your process capabilities by applying our procedural based manufacturing methods to your In this case, the cost of the machining represents just the 14% of the total cost of the product, where the raw material represent the remaining 86%vestment cost 24 or 2 82 msw ball mill, Supplier of metal cutting tooling and high impact custom cemented carbide, including ball nose end mills live chat; Autogenous mills, semiautogenous investment cost $ or msw ball mill deepcake6 天之前 Ball mills produce 1 to 50 ton/h power of which about 70 to 90 percent would pass a 200 mesh screen and the energy requirement of a ball mill is about 16 kWh/t In the case of the batchoperated mill, a measured Ball Mill Working Principle, Construction, Desktop High Energy Vibratory Ball Mill with One 80ml St St Jar new Manufacturer: Across International; VQN ball mills may be referred to as shaker mills, mixer mills or highenergy ball mills They can be used for both wet and dry grinding as well as to mix a variety of solids, suspended liquids and pastes This Used Ball Mills for sale in USA Machinio

.jpg)

Ball Mill SBM Ultrafine Powder Technology

Brief introduction The ball mill is the key equipment for crushing the material after it is crushed Ball mills are widely used in cement, silicate products, new building materials, refractory materials, fertilizers, ferrous and non 2024年8月28日 Uses of Ball Mill: Small capacity ball mills are used for the final grinding of drugs or grinding suspensions The highcapacity ball mills are used for milling ores before the manufacture of pharmaceutical chemicals Ball mills are an efficient tool for grinding many brittle and sticky materials into fine powderBall Mill Principle, Construction, Working, and More Soln Ball Mills Steel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container with journals at its axisOrbis Machinery Ball Mills Ball Mill Drive2024年8月16日 175 Wall Street Glendale Heights, IL 60139 Phone: 18002377079 Fax: 6309240340 : info@shimpoceramicsChoosing Your Ball Mill NIDECSHIMPO CERAMICS

Custom Ball Mill Products Neumann Machinery Company

Neumann Machinery Company (NMC) ball mills have a long and proven history going back to the early 1900’s The first mill designs originated from EIMCO Company originally located in Salt Lake City, Utah The current designs take advantage of advanced technologies in manufacturing, controls and devices NMC continues the tradition of reliable The small ball mill is a smallcapacity grinding equipment, which is defined relative to large ball millIt is generally suitable for smallscale production in the trial production stage Due to its small size and easy movement, small ball mill is sometimes referred to as mobile ball mill The mobile ball mill can be easily moved to the location of the material for onsite Small Ball Mill Mini Ball Mill for Small Scale Mineral Grindingallis chalmers svedala ball mill, year 1979 rebuilt 1998 used manufacturer: allischalmers; reference number: tt1812 allis chalmers svedala ball mill, year 1979 rebuilt 1998 allis chalmers svedala ball mill 13’ diameter x 21’ long rubberlined mill with siemensallis 2,000 hp 4000 volt 200 rpm sUsed Ball Mills (mineral processing) for sale in USA MachinioMetallurgist Mineral Processing Engineer

.jpg)

Factors Affect The Output and Quality of Ball

2023年12月28日 3 The ball mill is of good quality The better the quality of the ball mill, the more stable the performance of the ball mill will be during operation In addition, as for the lining plate of the ball mill’s wearing Planetary ball mills share the same design as other basic ball mills – a grinding jar filled with media and rotated on its own axis But their unique design takes advantage of centrifugal force and the Coriolis effect to grind materials to a very fine or even micron size These forces come into play asPlanetary Ball Mills 101 Union Process2023年11月21日 DS Smith, a provider of sustainable packaging solutions, unveiled a major investment to transform the paper mill's energy supply at its site in Normandy, France, near Rouen The project includes replacing DS Smith Makes €90M Sustainability Investment 4 天之前 NETZSCH Taurus Ball Mill, the pinnacle of fine and ultrafine grinding technology Achieve precise particle sizes with durable, lowmaintenance equipment Grinding Dispersing therefore low maintenance costs Troublefree, reliable operation Tailormade solutions available Lab Sizes available Product Inquiry Custom solutions and Taurus Ball Mill NETZSCH Grinding Dispersing

Dry Grinding Vs Wet Ball Mill Grinding Economy Ball Mill

2023年9月15日 At Economy Ball Mill, we’re a leading manufacturer of custommade ball mills for various industries We have many years of experience in designing and producing highquality ball mills that can meet your specific requirements We can provide both dry ball mills and wet ball mills, and can complete attritor mill barrel rebuildsThis 04L planetary ball mill machine features a compact design that fits in a glove box MSE PRO Bench Top Mini High Energy Vertical Planetary Ball Mill, 04L Size (4 x 100ml or 4 x 50 ml) Designed for holding four 50 ml size milling jars or 100 ml milling size jars (to be ordered separately) Can be placed in a glove box Should not be used in Planetary Ball Mills MSE Supplies LLC2024年1月28日 1 Cylindrical Shell: The ball mill consists of a hollow cylindrical shell that rotates about its axis The shell is usually made of steel, stainless steel, or rubber 2 Liners: An abrasionresistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding actionBall mill: Principles, construction, working, uses, merits, and Ball Mills, Pebble Mills, Material Processing Mills: For more than a century, Patterson has been the industry leading manufacturer of wet and dry grinding mills for size reduction or dispersal Patterson’s ball, pebble and rod mills are built to last We are still filling parts requests for mills sold over 60 years ago Patterson mills are available in a wide variety Ball Mills, Pebble Mills, Material Processing Mills Hatboro

What is the Difference Between Tumbling Mill and Ball Mill?

There are several types of tumbling mills, including ball mills, rod mills, and autogenous mills Ball mills are the most common type and are characterized by their cylindrical shape and the use of grinding media in the form of balls Rod mills are similar to ball mills but use long rods for grinding media2 天之前 The Laboratory Shop offers the full range of RETSCH ball mills A ball mill for powerful size reduction and homogenization RETSCH ball mills are available as mixer mills as well as planetary ball mills Mixer Mills grind and homogenize small sample volumes quickly and efficiently by impact and friction They are suitable for dry, wet and cryogenic Ball Mills The Laboratory Store LtdIt’s also the biggest investment equipment of mill plant, and the wastage of the ball mill has a direct relationship with mill plant operating costs Therefore, it is very important to maintain and overhaul the ball mill Cement Ball Mill Maintenance INFINITY FOR 2024年5月27日 The General Function of Ball Mills A ball mill is a grinder used for grinding and blending materials for mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering Ball Mills in the Mineral Processing Industry

.jpg)

Planetary Ball Mills MSE Supplies LLC

This 04L planetary ball mill machine features a compact design that fits in a glove box MSE PRO 4L (4 x 1L) Vertical High Energy Planetary Ball Mill with Touchscreen Controller Tired of old fashioned LCD control panels? 2022年11月30日 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size Ball Mill: Operating principles, components, Uses, 2024年9月4日 New and Used Ball Mills insights There are 1 Ball Mills for sale in Australia from which to choose Overall 97% of Ball Mills buyers enquire on only used listings, 3% on new and 979% on both new and used Ball Mills items Buyers usually enquire on 169 different Ball Mills classifieds before organising finance Ball Mills are listed between Ball Mills New or Used Ball Mills for sale AustraliaThe Planetary Ball Mill PM 300 is a powerful and ergonomic benchtop model with two grinding stations for grinding jar volumes up to 500 ml This setup allows for processing up to 2 x 220 ml sample material per batch Thanks to the high maximum speed of 800 rpm, extremely high centrifugal forces result in very high pulverization energy and Planetary Ball Mill PM 300 RETSCH laboratory equipment

The Ultimate Guide to Ball Mills Miningpedia

2019年8月14日 Moreover, the price of ball mills is relatively expensive among many beneficiation equipment Therefore,after successfully purchasing a ball mill, it is necessary to carry out daily maintenance and maintenance of the ball mill The replacement of the ball mill liner is an indispensable maintenance workinvestment cost 24 or 2 82 msw ball mill Ginning mill project ginning mills for sale ginning mill for sale apartmanlipnorent 47 profile on cotton ginning plant embassy of pdf cotton ginning is the process of separating cotton seed from the lint so that the lint will be baled and goes to textile industries forInvestment cost 24 or 2 82 msw ball millSmall ginning mills Investment Cost Or Msw Ball Mill MC Machinery2022年7月12日 Vertimill® has 50% less footprint than a ball mill Lower operating cost Vertimill® is an energy efficient grinding machine They tend to grind more efficiently than, for example, ball mills with feeds as coarse as 6 mm to products finer than 10 microns This provides up to a 40% higher energy efficiencyStirred mills MetsoThe initial investment cost (turnkey cost) includes the exworks price of the equipment needed (wind turbines, battery bank, electronic equipment, etc) and the corresponding installation cost The application of new technological achievements and the economies of scale decrease most system component prices in the international marketinvestment cost $ OR MSW ball mill forndelpontes